Kev ua tau zoo thiab kev ua haujlwm zoo nyob ntawm qhov muaj cov cuab yeej tsim nyog, khoom siv thiab kev txawj ntse. Kev paub txog kev xav kuj tseem cuam tshuam rau kev vam meej hauv kev lag luam, txawm tias nws yog dab tsi. Vuam yog suav tias yog ib qho ntawm feem ntau.

hom haujlwm no yuav tsum muaj cov khoom siv, khoom siv, kev ua haujlwm, nrog rau kev paub txog kev xav. Tau paub txog cov ntaub ntawv tsim nyog, ib tus neeg tau txais lub tswv yim ntawm qhov seam yog dab tsi, kev faib cov welds muaj nyob thiab yuav ua li cas xaiv qhov kev xaiv zoo tshaj plaws rau kev sib txuas ntawm ntau yam khoom hlau.

Yuav ua li cas yog weld?

Thaum lub sijhawm vuam, peb ntu hlau tau koom nrog hauv cov txheej txheem: ob daim yog fastened ua ke nrog kev pab ntawm peb, uas ua raws li ib tug electrode.qog. Nyob rau ntawm qhov sib txuas ntawm cov khoom hlau nrog ib leeg, cov txheej txheem thermal tshwm sim, tsim ib lub seam. Yog li, lub seam yog ib feem ntawm cov qauv hlau tau los ntawm kev ua ntawm fused thiab solidified hlau.

Koj tuaj yeem txuas txhua yam hlau los ntawm vuam. Lawv muaj lawv tus kheej cov yam ntxwv, raws li ib tug tej yam fastening yog xaiv. Kev faib tawm ntawm welds yog tsim nyob ntawm seb hom adhesion, khoom siv thiab lwm yam tsis. Txhua qhov kev sib txuas muaj nws cov lus qhia thiab nws qhov kev txiav txim ua tiav.

Sizes

Muaj kev faib cov welds los ntawm qhov ntev. Nyob ntawm qhov loj me, cov vuam seams yog:

- Short. Qhov loj me tsis pub tshaj 30 cm. Cov seam zoo li no tshwm sim los ntawm kev vuam ua nyob rau hauv ib qho kev taw qhia txij thaum pib mus txog rau thaum xaus.

- Average. Seam ntev - los ntawm 30 cm mus rau 1 meter. Cov seams yog welded los ntawm nruab nrab mus rau cov npoo. Rau lawv, txoj kev thim rov qab yog qhov zoo tagnrho. Nws lub ntsiab lus nyob rau hauv lub fact tias tag nrho cov seam yog muab faib ua ob peb seem, uas yog alternated los ntawm welding. Txhua ntu muaj qhov ntev ntawm 10 txog 30 cm.

- Ntev (dhau ib meter). Lawv tau welded tib yam li nruab nrab seams, nrog rau qhov sib txawv tsuas yog tias cov seem ntawm no yuav ntau dua.

Yam welded joints

Kev faib tawm ntawm welds kuj tau ua raws li hom fastening. Muaj plaub hom kev sib txuas:

- pob;

- T-puab;

- overlapping;

- angular.

hom ntau tshaj

Thaum lub pob tw sib txuas, lub thickness ntawm cov khoom raug coj mus rau hauv tus account. Qhov no txuag tau ntau yam khoom.

Lub pob tw clutch yog suav tias yog qhov nrov tshaj plaws. Qhov no yog vim qhov tseeb tias cov txheej txheem vuam no yog qhov ceev tshaj plaws thiab pheej yig tshaj plaws.

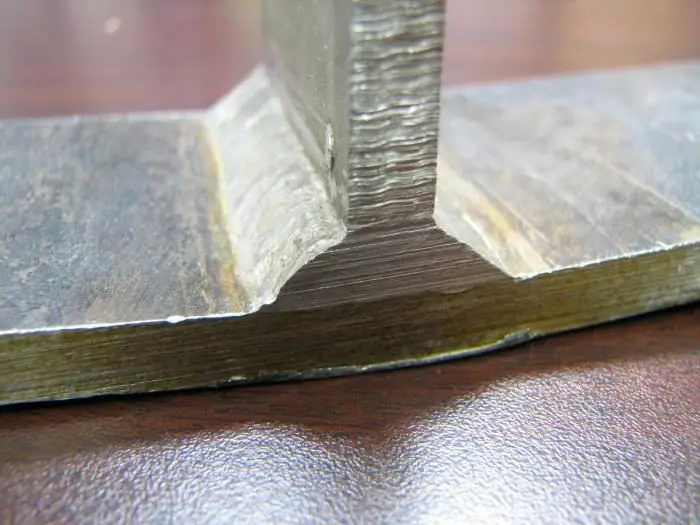

T-welding. Nta thiab cov lus pom zoo

Hom clutch no yog tus yam ntxwv los ntawm T-shaped kev sib txuas ntawm cov khoom hlau. Raws li nyob rau hauv lub pob tw, kev saib xyuas tshwj xeeb yog them rau cov tuab ntawm cov hlau, nyob ntawm seb cov seams yog ib sab thiab ob sab.

Thaum siv hom clutch no, koj yuav tsum ua raws li cov lus pom zoo hauv qab no:

- Thaum ua T-welding thaum koom nrog ob yam khoom nrog cov thicknesses sib txawv, nws yog ib qho tsim nyog yuav tsum tuav lub vuam teeb sib txuas nrog cov khoom tuab ntawm lub kaum sab xis ntawm 60 degrees.

- Kev ua haujlwm vuam tuaj yeem ua kom yooj yim los ntawm kev tso cov qauv "hauv lub nkoj". Txoj hauj lwm no ntawm lub workpiece yuav tshem tawm cov undercuts, tsis tau undercooked cheeb tsam, uas yog suav hais tias yog cov feem ntau tsis xws luag rau hom adhesion.

- Yog tias ib qho dhau ntawm lub vuam teeb tsis zoo, vim qhov chaw tsis zoo yuav nyob twj ywm, lawv yuav tsum tau welded los ntawm vibrating lub vuam electrodes.

- Hauv T-joint, ib sab vuam tuaj yeem txwv. Txhawm rau ua qhov no, koj yuav tsum siv vuamkhoom siv Oineo Tronic Pulse, uas tso cai rau RW-brewing.

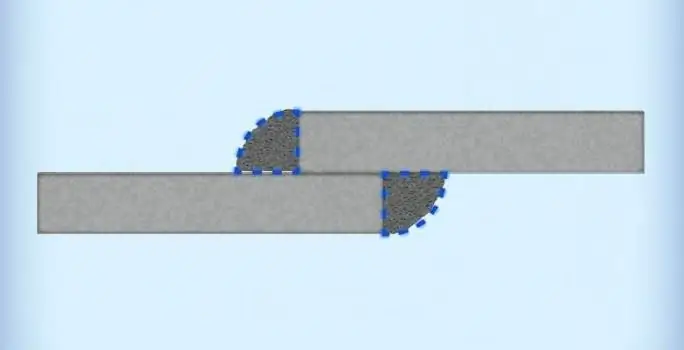

lav welding

Lub hauv paus ntsiab lus ntawm hom kev sib txuas no yog ob sab vuam ntawm cov khoom, lub thickness tsis ntau tshaj 1 cm. Qhov kev vuam no yog siv rau hauv cov xwm txheej uas yuav tsum tau tiv thaiv kom tsis txhob ya raws ntawm qhov sib txawv. cov ntawv hlau. Raws li qhov tshwm sim ntawm txoj haujlwm no, ob txoj hlua khi tau tsim. Hom weld no suav hais tias siv tau ntev thiab tsis siv nyiaj vim nws xav tau cov ntaub ntawv ntxiv los ua haujlwm.

Ntsuag tuav

hom vuam no yog siv los txuas cov khoom siv hlau nyob rau hauv ib txoj hauj lwm perpendicular rau ib leeg. Nyob ntawm qhov tuab ntawm cov nplooj ntawv, lub kaum sab xis vuam yog tus cwj pwm los ntawm qhov muaj lossis tsis muaj cov npoo beveled. Yog tias tsim nyog, hom kev sib txuas no yog tsim los ntawm sab hauv ntawm cov khoom.

Shapes of welds

Kev faib cov welds raws li cov duab ntawm sab nrauv txhais tau peb hom:

- Paj. Ua tau zoo nyob rau hauv kev ua haujlwm zoo thiab hloov pauv, txij li cov seams (xws li cov concave) tsis muaj qhov kev ntxhov siab uas tuaj yeem ua rau cov te ntse thiab ua kom puas welding daim ntawv cog lus.

- Nkauj. Lub concavity ntawm weld, tsis ntau tshaj 0.3 cm, yog xam tau tias yog ib qho kev pom zoo, txwv tsis pub, lub concavity ntawm weld yog suav tias yog ntau dhau thiab suav hais tias yog ib qho tsis xws luag. Qib ntawm concavity yog ntsuas nyob rau hauv cheeb tsam uas muaj qhov loj tshajdeflection.

- Txoj hlua khi. Lawv tshwm sim los ntawm tsub zuj zuj ntawm ib tug loj npaum li cas ntawm solidified hlau thiab raug xam tias yog uneconomical. Tab sis nyob rau tib lub sij hawm, ib tug welded sib koom ua ke uas muab ib tug convex seam yog zoo nyob rau hauv zoo li qub load tshaj ib tug sib koom nrog ib tug ca los yog concave weld. Lub convexity Performance index yog qhov kev ncua deb ntawm qhov chaw ntawm lub hauv paus hlau mus rau qhov chaw ntawm qhov loj tshaj protrusion. Bulges tsis tshaj 0.2 cm rau hauv qab vuam thiab tsis pub tshaj 0.3 cm rau vuam ua nyob rau hauv lwm txoj hauj lwm yog xam raws li tus qauv.

Kev faib cov welds los ntawm txoj haujlwm hauv qhov chaw

Raws li qhov kev tso kawm ntawm qhov chaw, muaj plaub hom seams, txhua tus muaj nws tus yam ntxwv thiab cov lus pom zoo rau vuam:

- Txoj hlua khi. Nyob rau hauv ib qho kev nam, lawv suav hais tias yog qhov yooj yim tshaj plaws. Vuam ntawm cov seams qis yog nqa tawm ntawm qhov chaw tiaj tus hauv txoj haujlwm los ntawm hauv qab. Cov txheej txheem no yog tus cwj pwm los ntawm kev ua haujlwm siab thiab zoo. Qhov no yog vim muaj kev nyiam ntau dua rau cov welder. Cov hlau molten yog qhia los ntawm nws qhov hnyav rau hauv lub pas dej welded nyob rau hauv txoj hauj lwm kab rov tav. Nws yog ib qho yooj yim ua raws li kev ua noj ntawm cov seams hauv qab. Txoj hauj lwm tiav sai sai.

- Kab rov tav seams. Vuam yog ib qho nyuaj me ntsis. Qhov teeb meem yog tias cov hlau melted, nyob rau hauv lub zog ntawm nws qhov hnyav, ntws mus rau hauv qab ntug. Qhov no yuav ua rau muaj kev cuam tshuam ntawm ntug saum toj.

- Txoj hlua khi. Lawv yog cov txiaj ntsig ntawm kev koom nrog cov khoom siv hlau tso rau hauv lub dav hlau ntsug.

- Qab nthab seams. Qhov no vuam yog xamqhov nyuaj tshaj plaws thiab lub luag haujlwm. Nws yog tus cwj pwm los ntawm kev nplij siab tsawg. Thaum lub sij hawm vuam txheej txheem, kev tso tawm ntawm slags thiab gases yuav nyuaj dua. Tsis yog txhua tus tuaj yeem tiv nrog qhov kev lag luam no, xav tau ntau yam kev paub, vim tias nws tsis yooj yim los khaws slag ntog ntawm koj lub ntsej muag thaum ua haujlwm. Nws yog ib qho tseem ceeb los soj ntsuam qhov zoo thiab lub zog ntawm kev sib txuas.

welds thiab pob qij txha txheeb xyuas li cas?

Kev faib tawm thiab kev tsim cov welds yog tsim los siv cov cim tshwj xeeb, kab thiab hu xov tooj. Lawv tau muab tso rau ntawm lub rooj sib txoos kos duab thiab ntawm tus qauv nws tus kheej. Kev faib tawm ntawm cov pob qij txha welded thiab seams yog qhia, raws li cov ntaub ntawv tswj hwm, siv cov kab tshwj xeeb uas tuaj yeem ua tau ruaj khov lossis dashed. Nruam qhia pom welds, dashed qhia pom tsis pom.

Cov cim seam tau muab tso rau ntawm lub txee los ntawm kev hu xov tooj (yog tias lub seam nyob rau sab pem hauv ntej). Los yog, conversely, nyob rau hauv lub txee, yog hais tias lub seam yog muab tso rau ntawm lub rov qab sab. Cov cim qhia txog kev faib cov welds, lawv qhov tsis sib xws, kev tso kawm ntawm ntu rau vuam.

Cov cim ntxiv nyob ib sab ntawm lub cim tseem ceeb. Lawv muaj cov ntaub ntawv txhawb nqa:

- txog tshem tawm qhov kev txhim kho vuam;

- ntawm kev kho deg rau kev hloov pauv mus rau lub hauv paus hlau thiab tiv thaiv sagging thiab unevenness;

- txog txoj kab uas ua seam (yog nws kaw).

Rau cov qauv tsim thiab cov khoom ntawm tib GOST, cov qauv cim thiab cov kev xav tau raug muab. Yog hais tias tus qauv muaj tib seams, ces lawvNws yog qhov zoo dua los muab cov naj npawb serial thiab tawg rau hauv pawg, uas kuj tau muab cov lej rau kev yooj yim. Tag nrho cov ntaub ntawv hais txog tus naj npawb ntawm pawg thiab seams yuav tsum tau qhia hauv daim ntawv tswj hwm.

Seam txoj hauj lwm

Kev faib cov welds yog nyob ntawm txoj haujlwm ntawm qhov vuam. Lawv yog:

- ib leeg ib sab. Tsim los ntawm cov ntaub ntawv vuam, lub thickness tsis pub tshaj 0.4 cm.

- ob sab. Muaj tshwm sim thaum lub sij hawm ob sab vuam ntawm cov ntawv hlau nrog lub thickness ntawm 0.8 cm. Rau txhua qhov kev sib txuas, nws raug nquahu kom tawm 2 hli qhov sib txawv los xyuas kom meej adhesion.

Yuav muaj qhov tsis zoo

Kev tsis xws luag thaum vuam tuaj yeem tshwm sim vim muaj qhov tam sim no ntau dhau thiab arc voltages. Nws kuj tuaj yeem yog qhov tshwm sim ntawm kev siv tsis raug ntawm cov electrodes. Kev faib tawm ntawm weld defects los ntawm lawv qhov chaw:

- Nyob hauv. Txhawm rau txheeb xyuas lawv, siv cov txheej txheem uas muaj kev tswj hwm: tsis txhob rhuav tshem cov qauv, rhuav tshem tag nrho lossis ib nrab.

- Tawm sab nraum zoov. Lawv raug txheeb xyuas tau yooj yim los ntawm kev kuaj xyuas sab nraud.

Vim yog ua txhaum txoj cai vuam vim tsis muaj kev tsim nyog, kev npaj ua haujlwm tsis txaus, kev ntsuas tsis raug, qhov tsis zoo tau muab faib ua:

- Tsis muaj fusion. Nws manifests nws tus kheej nyob rau hauv lub zos tsis muaj fusions ntawm cov ntsiab lus txuas. Qhov tsis xws luag ua rau muaj kev ntxhov siab ntau ntxiv thiab txo qis hauv ntu ntu ntawm qhov vuam. Ib qho kev tsim nrog xws li qhov tsis xws luag yog tus cwj pwm los ntawm kev txo lub zog thiab kev ntseeg siab. Ua rau tsis muaj fusionmuaj peev xwm ua tau ob qho tib si tsis txaus lub zog tam sim no thiab vuam hauv hom ceev.

- Ntxhais. Qhov tsis xws luag muaj nyob rau hauv lub zos txo nyob rau hauv lub thickness ntawm lub hauv paus hlau. Qhov teeb meem no tshwm sim ze ntawm cov npoo ntawm welds.

- Burn. Qhov tsis xws luag zoo li kab noj hniav hauv qhov vuam. Nws tshwm sim vim qhov to ntawm cov hlau molten los ntawm lub pas dej ua ke. Kev kub hnyiab yog qhov tsis txaus ntseeg thiab yuav tsum tau kho sai sai.

- Ib qhov tsis sib khi los yog kev nyuaj siab. tshwm sim vim arc tawg thaum mus kom ze rau qhov kawg ntawm seam.

- Influx. Qhov tsis xws luag manifests nws tus kheej nyob rau hauv lub ntws ntawm cov hlau weld mus rau lub hauv paus hlau tsis muaj lawv fusion.

Kev tsis zoo tuaj yeem los ntawm ntau qhov laj thawj, tab sis lawv tuaj yeem txo qhov adhesion, serviceability, raug thiab tsos.